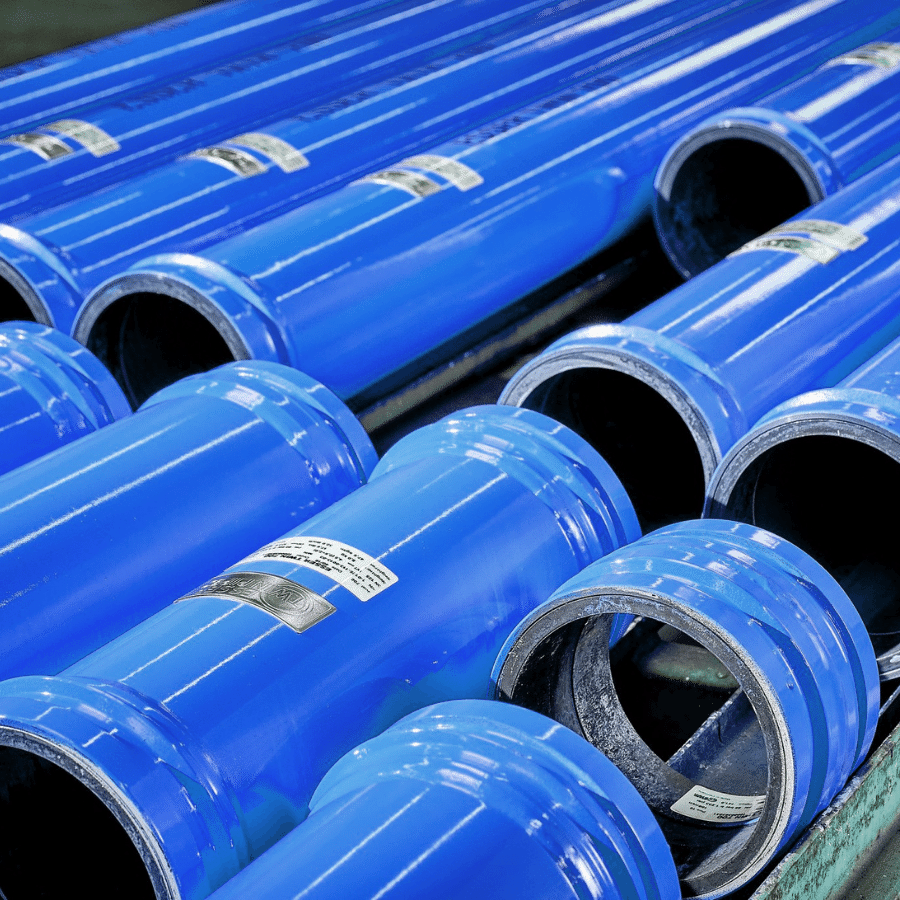

Meet the twin-walled hardened steel pipe that is ideal of hydraulic and pneumatic conveying of abrasive materials. This versatile series of pipes is highly adaptable for your industrial needs, from concrete pumping to mining and beyond. The inner layer is uniformly hardened to 63 HRC. The pipe wall thickness is determined based on the application parameters. This series of abrasion resistant pipes can be equipped with a variety of weld-ends or flange connections and can be produced in special shapes such as reducers, T-pieces, and Y-pieces. The ESSER TWIN 700 series of hardened steel pipes has a service life 5 to 6 times longer than conventional steel pipes and are trusted in industrial operations worldwide.

The ESSER TWIN 700 is the abrasion resistant, twin-walled pipe trusted by concrete pumping operations worldwide. Able to handle the highly abrasive concrete mixture as it moves from the concrete pump, the TWIN 700 series withstands severe pressure while protecting the inner wear layer from bending forces.

When concrete needs to reach extremely high or low locations, we provide the pipes that make it possible. Our abrasion resistant ESSER TWIN 700 series is uniquely suited to high-rise construction because of its twin-walled construction and ability to withstand severe abrasion and bending pressures.

With a pneumatic operating pressure up to 10 bar and a test pressure up to 20 bar, the TWIN 700 is ideal for pneumatic conveying. Our twin-walled pipe often serves as a straight line component as part of our QuickFix smart pipe system. This works in tandem with higher hardness bends and outlet pipes to provide durable and reliable performance.

The twin-walled hardened steel of the TWIN 700 series is the perfect for mining applications that require abrasion resistance in tough conditions. With a hardness of 63 HRC, your operation will experience less pipe wear and, in turn, less downtime, improving production and efficiency. Mines trust ESSER for pipelines that require less replacement and maintenance.

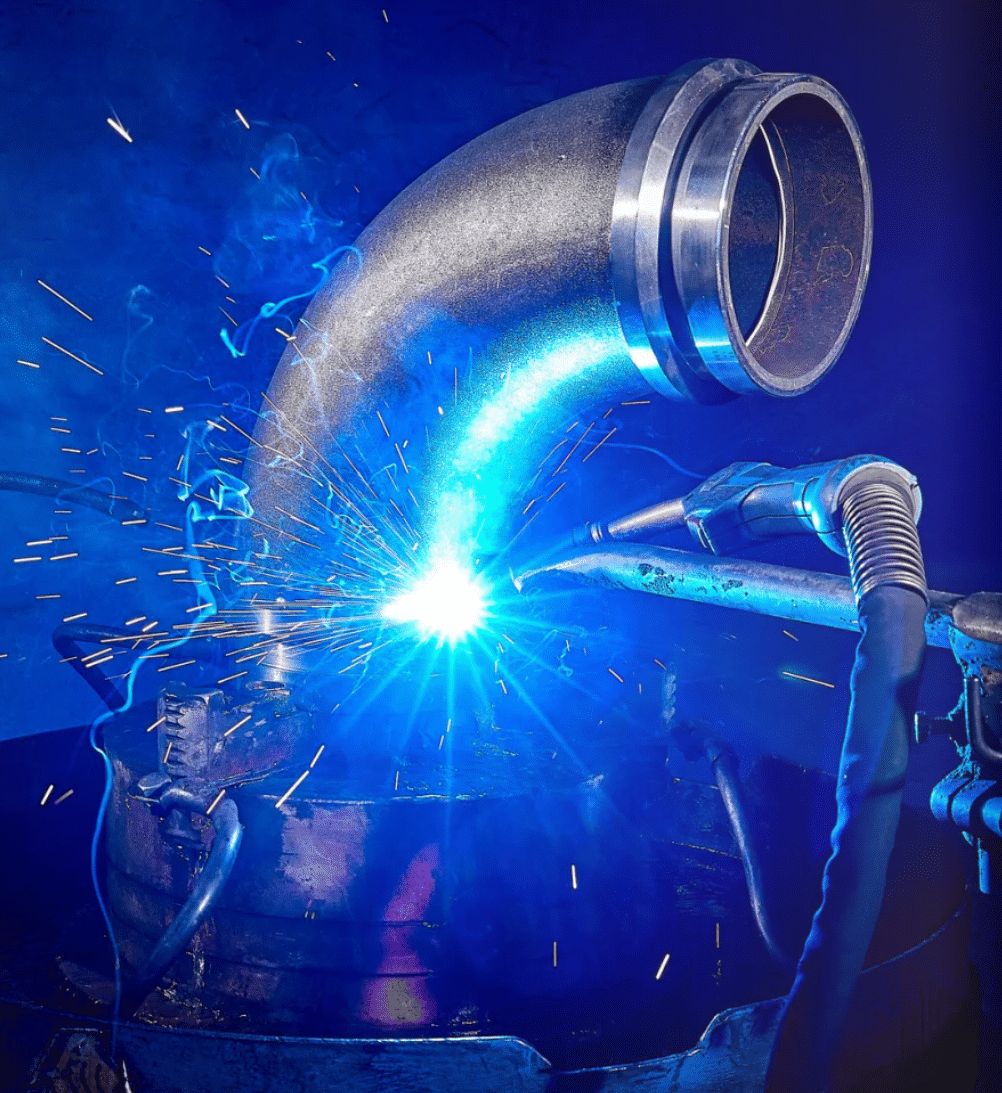

Access the products you need for long-term performance thanks to our production process focused on quality and durability.

With consistent performance comes less time spent on maintenance or repairs—one of the benefits of choosing Esser.

Lower your replacement and repair costs with custom pipe solutions matched to your individual operation's needs.

Ensure you're meeting your sustainability goals by choosing a piping partner with a long-standing commitment to environmentally friendly practices.