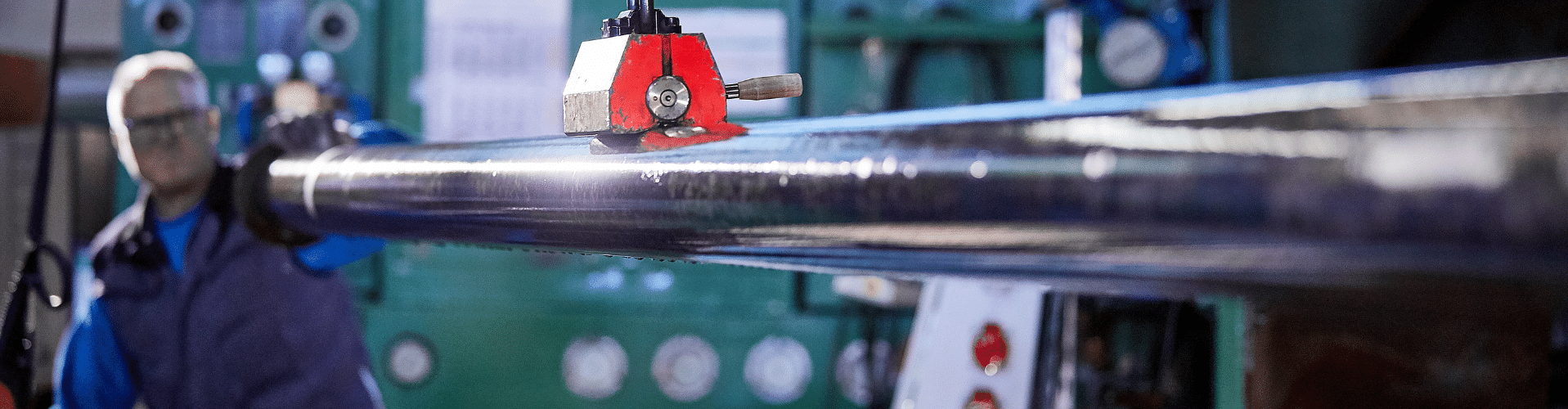

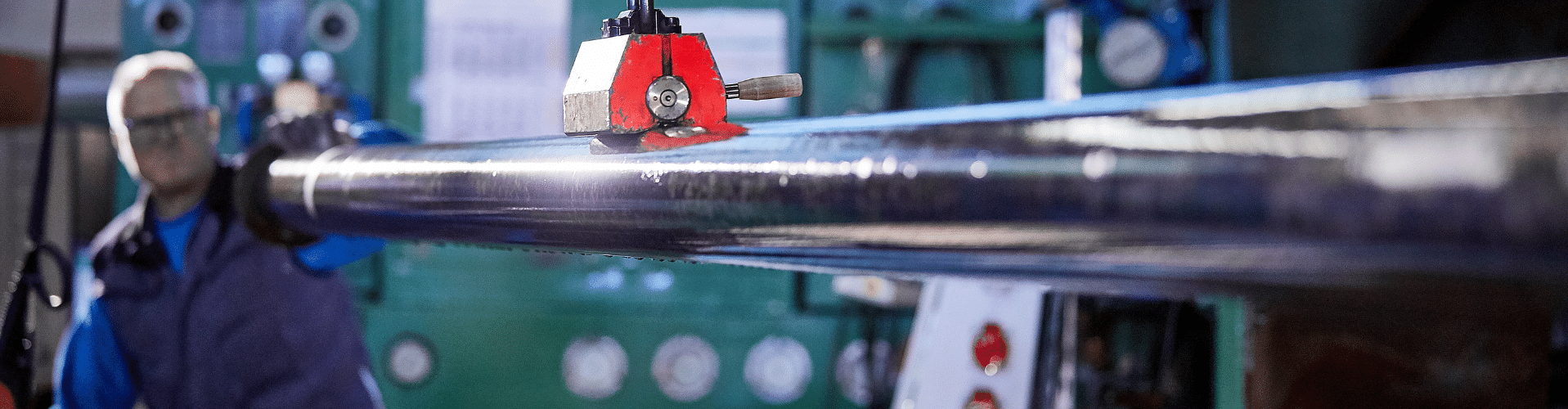

We’ve brought together continuous innovation and worldwide field experience to create the highest quality hardened pipe for concrete pumping, mining applications, pneumatic conveying, and more. Clients around the world have relied on us for twin-walled, wear resistant pipe solutions for decades. Find out how we can help you achieve first-class performance with our abrasion resistant pipes.

[newsletter]

As one of the world’s leading steel pipe manufacturers, we develop hardened pipes, couplings, and fittings of the highest quality. We meet customer-specific requirements for wear resistant products with a commitment to production safety and reliability. Our in-house, patented production process ensures that our twin-walled pipe components perform consistently across industries.

We also manufacture special shapes for complex pipe isometries to ensure the optimum function of your application.

Our range of accessories includes couplings, seals, O-rings, cleaning equipment, grounding cables, and more.

So, when it comes to your industrial pipe and accessories, discover how Esser can help you work more efficiently and safely.

From durable twin-walled pipe solutions to ultra-wear-resistant pipes for the most complex job sites, ESSER makes the right hardened pipe for your industrial operation. Find out more about our abrasion resistant pipe options below.

We provide a wide range of accessories for our hardened pipes and conveying lines, including shut-off valves, couplings, cleaning equipment, and more. nec ullamcorper mattis, pulvinar dapibus leo.

Industrial operations around the world use our hardened pipes, couplings, and accessories in hydraulic or pneumatic applications in the most challenging conditions. Today, you can find our piping systems in operation on nearly every continent across industries, including concrete pumping, building construction, mining (building material transport and backfill), plastics manufacturing, cement plants, building materials, foundries, inorganic pigment manufacturing, sewage sludge handling, and more.

We provide quality products known worldwide, expert consulting and engineering, high price-performance ratio, and partnership in custom solutions.

Find out the many reasons why Esser may be right for you.

Talk to an Esser expert about the appropriate wear resistant products for your application.