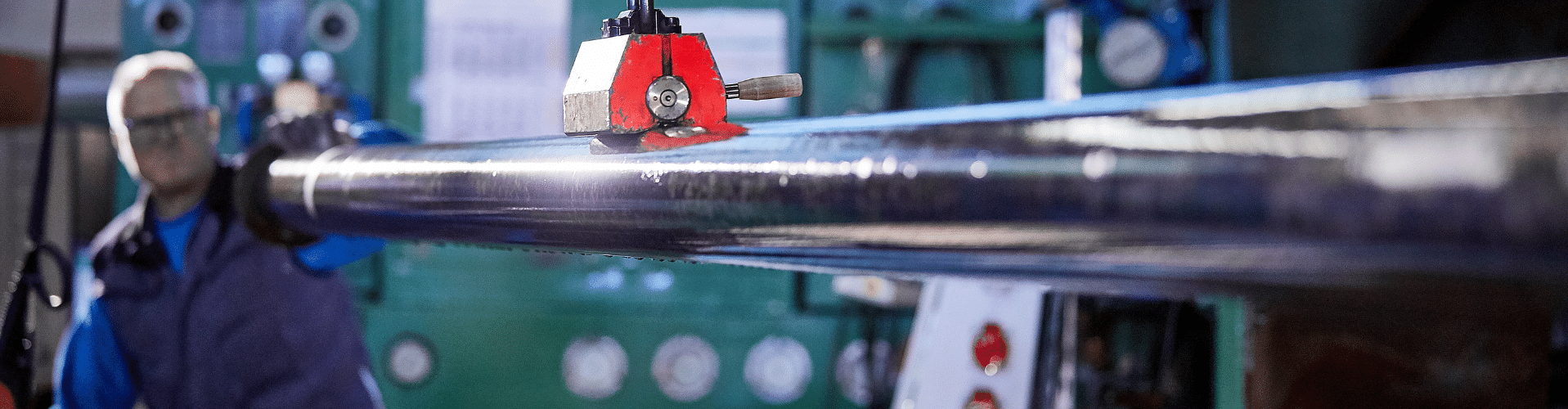

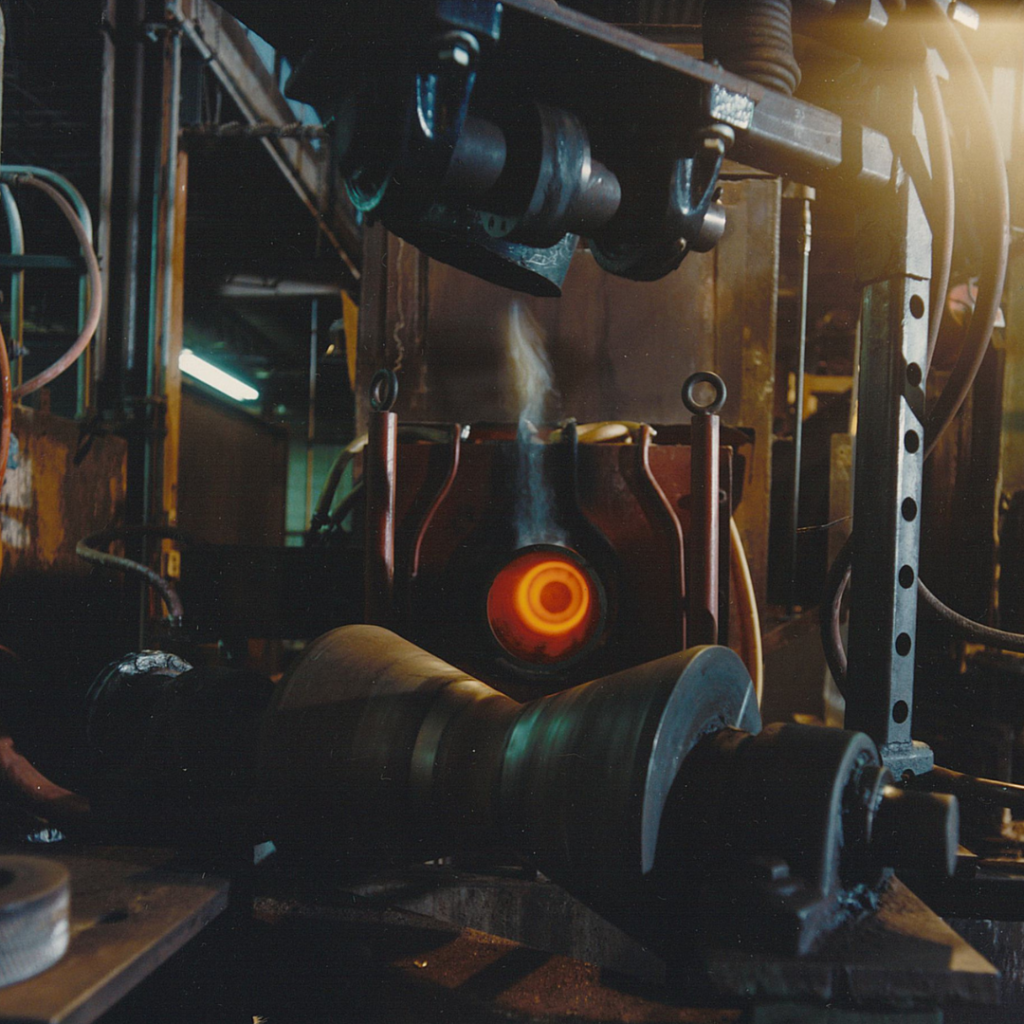

Since 1948, Esser has been developing piping systems that are among the leading systems on the market today. Located in Warstein, Germany, we service customers in more than ten industries around the world, applying the same unique blend of engineering, quality and technological know-how to every project. Our products are known for their reliability and durability. They are precisely tailored to the requirements of each application. Our twin-walled pipe is hard to compare with other products on the market. The inner tubes are manufactured using our patented production process. This enables us to achieve hardness levels at the end of the Rockwell scale and thus a high resistance to wear. The outer tube retains its compressive strength. This makes our pipe components the ideal product when it comes to conveying abrasive materials under pressure – whether hydraulically or pneumatically. We manufacture standardized components on-site that are available at short notice. Customized solutions are also part of our portfolio. At Esser, we meet or exceed the highest international safety standards. This gives our customers the peace of mind they need for productive and efficient operations. As a sustainable company, we attach great importance to protecting our environment and using resources conscientiously. Investments in environmentally friendly production machines, the reduction of power losses and the expansion of renewable energies serve to reduce our CO2 footprint. Our production site is in the immediate vicinity of a nature reserve, in the middle of the “Arnsberg Forest” nature park. What we protect, we see every day.