Die Vielfalt der Anwendungsbereiche von ESSER-Rohren ist in der Tat außergewöhnlich. Neben Rohren für den Bergbau sind wir auch Partner einer deutlich empfindlicheren Branche – der Glasherstellung. Glas ist ein uraltes Produkt und findet heutzutage breite Anwendung. Es dient nicht nur als Baustoff für Architektur und Verpackungen, sondern ist auch ein wesentlicher Bestandteil von Geschirr, Optik und Kunst.

Der wichtigste Rohstoff für die Glasherstellung ist hochabrasiver Quarzsand (SiO₂), der aufgrund seiner Härte von 8 auf der Mohs-Skala (ca. 1120 HV) maßgeblich für den extremen Verschleiß der Funktionsteile von Förderanlagen verantwortlich ist. Auch Recyclingprodukte wie Altglasscherben belasten Förderrohre aus normalem Stahl stark. Daher sind viele Glashersteller auf alternative Fördersysteme wie Band- oder Rohrförderer umgestiegen, um die in der Glasproduktion verwendeten Schüttgüter zu transportieren.

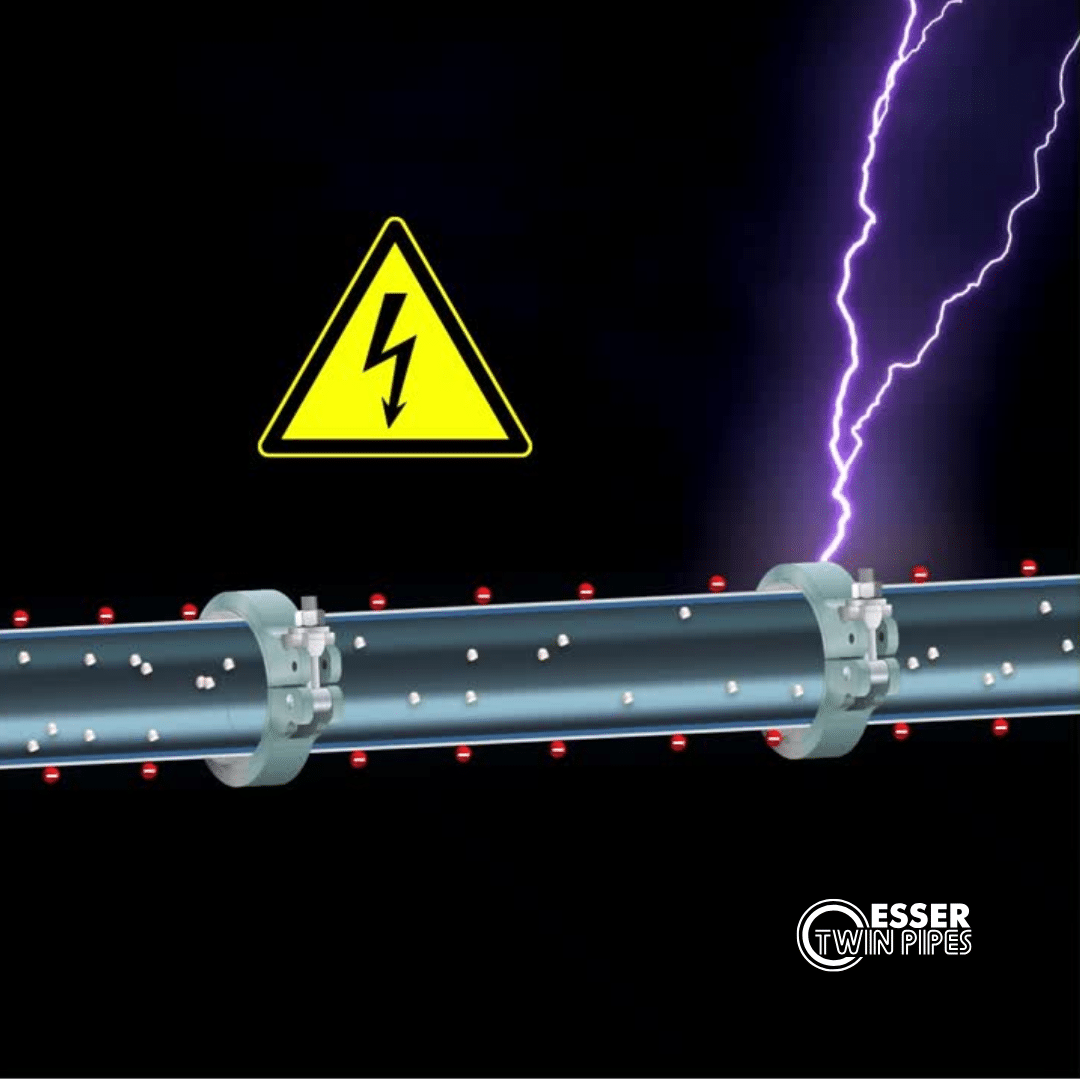

Pneumatische Fördersysteme werden dennoch aus verschiedenen Gründen weiterhin in vielen Arbeitsprozessen eingesetzt, beispielsweise zur Steuerung von Ladungen und deren Dosierung. Integrierte Dosierwaagen tragen zur Sicherstellung der Dosierungsgenauigkeit bei und überwachen die Charge im Allgemeinen, indem sie eine optimale und korrekte Menge an Schüttgutzusätzen gewährleisten.

Der Einsatz von ESSER-Komponenten macht die pneumatische Förderung für die Glasindustrie noch attraktiver. Unser Fokus liegt darauf, mit unserem Know-how und unserer Erfahrung maßgeschneiderte Lösungen zu entwickeln, die Ihren spezifischen Anforderungen entsprechen. Damit sind wir ein starker Partner für diese sensible Branche.

Hier geht es zu unserem Katalog für pneumatische Anwendungen